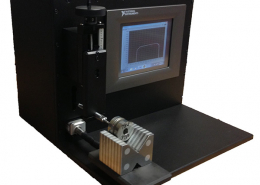

Precise Highly Accurate Laser Measurement

Young Solutions Inc.

Understanding 3D Machine Vision Concepts

3D machine vision is revolutionizing industries by enhancing automation, quality control, and data analysis processes. Unlike traditional 2D vision systems, which capture flat images, 3D machine vision systems provide depth information, allowing for a more comprehensive understanding of objects and environments. Let’s delve into the key concepts, applications, and benefits of 3D machine vision.

Key Concepts of 3D Machine Vision

1. Depth Perception: The core advantage of 3D machine vision systems is their ability to perceive depth. By capturing three-dimensional data, these systems can accurately measure the distance between objects and their spatial relationships.

2. Stereoscopic Vision: This technique mimics human binocular vision by using two or more cameras to capture images from different angles. The images are then combined to create a 3D representation of the scene.

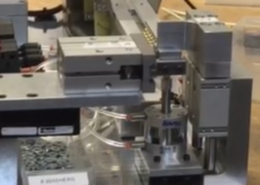

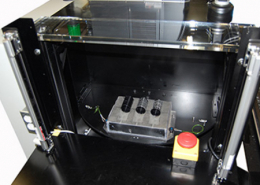

3. Structured Light: Structured light systems project a known pattern, such as grids or stripes, onto the object. The deformation of this pattern when viewed from different angles is analyzed to reconstruct the 3D shape of the object.

4. Time-of-Flight (ToF): ToF systems measure the time it takes for a laser or LED light to travel to an object and back to the sensor. This data is used to calculate the distance and create a 3D point cloud of the object.

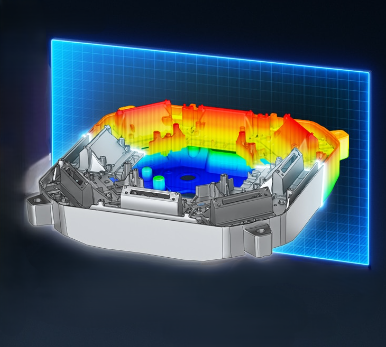

5. Point Clouds: A point cloud is a collection of data points in a three-dimensional coordinate system. Each point represents a point on the surface of an object, allowing for detailed 3D modeling and analysis.

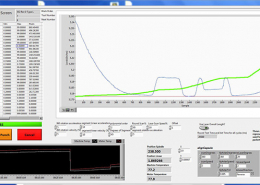

6. Image Processing Algorithms: Advanced algorithms process the 3D data to extract meaningful information, such as object dimensions, surface defects, and spatial orientation. These algorithms are crucial for applications like quality control and robotic guidance.

Applications of 3D Machine Vision

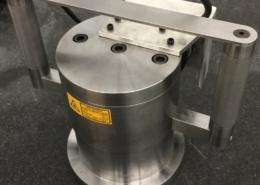

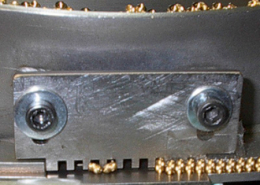

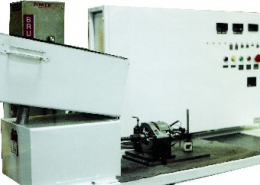

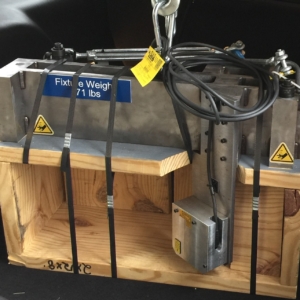

1. Quality Control: 3D machine vision systems are used to inspect products for defects, measure dimensions, and ensure that parts meet strict tolerances. This is particularly important in industries like automotive and aerospace, where precision is critical.

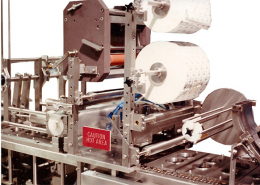

2. Robotic Guidance: 3D vision enables robots to navigate complex environments, grasp objects accurately, and perform assembly tasks with high precision. This enhances the flexibility and efficiency of automated production lines.

3. Reverse Engineering: By capturing detailed 3D models of existing objects, machine vision systems facilitate reverse engineering, allowing manufacturers to recreate or modify parts without original designs.

4. Logistics and Warehousing: 3D vision systems improve inventory management, package sorting, and automated storage and retrieval systems by providing accurate spatial information.

5. Medical Imaging: In healthcare, 3D vision technologies are used for medical imaging, surgical guidance, and the creation of customized prosthetics and implants.

Benefits of 3D Machine Vision

1. Increased Accuracy: 3D vision systems provide highly accurate measurements, reducing errors and improving product quality.

2. Enhanced Automation: By enabling robots and automated systems to perceive depth, 3D vision enhances their ability to perform complex tasks autonomously.

3. Improved Efficiency: Automated inspection and measurement processes reduce the time and labor required for quality control, increasing overall efficiency.

4. Better Data Analysis: The rich data captured by 3D vision systems enables more comprehensive analysis, leading to better decision-making and process optimization.

Future Prospects of 3D Machine Vision

The future of 3D machine vision is bright, with ongoing advancements in sensor technology, image processing algorithms, and artificial intelligence. As these technologies evolve, 3D machine vision systems will become more accessible, affordable, and capable, driving further innovation across various industries.

In conclusion, 3D machine vision is transforming the way we perceive and interact with the world. By providing depth information and enhancing automation, these systems are opening new possibilities for precision, efficiency, and innovation in manufacturing, healthcare, logistics, and beyond.

Is there a specific application of 3D machine vision you’re interested in exploring further?