The Impact of Temperature and Vibration on Precision Measurements.

Young Solutions Inc.

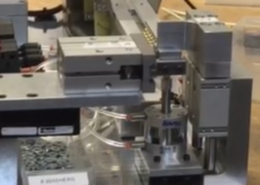

Coordinate measuring machine measures aluminium parts with touch probe.

The Impact of Temperature and Vibration on Precision Measurements

Precision measurements are crucial in various industries, from aerospace to automotive manufacturing. However, achieving accurate and reliable measurements can be challenging due to external factors like temperature and vibration. Understanding how these factors affect precision measurements is essential for ensuring product quality and compliance with industry standards.

Temperature Effects on Precision Measurements

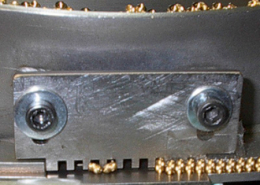

Temperature variations can significantly impact measurement accuracy. When the temperature of the object being measured or the measuring instrument changes, it can cause the materials to expand or contract. This dimensional change can lead to errors in the measurement results. For example, a steel micrometer and a copper shaft will expand and contract at different rates when subjected to temperature changes, leading to inaccuracies.

To minimize temperature-related errors, it is essential to maintain equal temperatures between the measured object and the standard instrument. This can be achieved by allowing the materials to reach thermal equilibrium before taking measurements. Additionally, measurement rooms are often maintained at a standard temperature, typically around 20° C, to ensure consistent results.

Vibration Effects on Precision Measurements

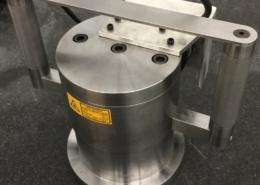

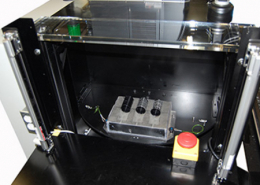

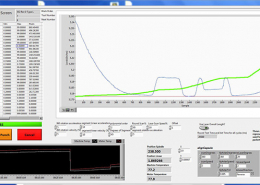

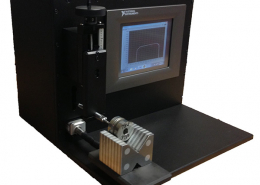

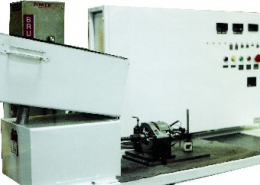

Vibration is another critical factor that can affect measurement accuracy. External vibrations from surrounding equipment, human activity, or even the measurement process itself can introduce noise and disrupt the measurement system. For instance, vibrations can cause displacement of the sample or measurement platform, leading to inaccurate readings. In Coordinate Measuring Machines, vibrations can compromise the integrity of measurements.

To mitigate vibration-related errors, it is essential to use vibration isolation systems and ensure that the measurement environment is free from external vibrations. Proper maintenance of the measurement equipment, such as leveling and regular checks for wear and tear, can also help reduce vibration-induced inaccuracies.

Conclusion

Temperature and vibration are two significant factors that can impact precision measurements. By understanding their effects and implementing appropriate measures to control them, manufacturers can ensure accurate and reliable measurements, leading to higher quality products and compliance with industry standards.

We find many manufacturers that are improving their processes to measure at precisions of .0001” or less are being impacted by these factors but to those taking the measurements the influence might not be readily apparent.

Would you like to know more about specific methods to control temperature and vibration in precision measurement environments? Contact us today.