https://www.youngsolutions.net/wp-content/uploads/2024/12/IMG_1389.1.jpg

1630

2174

Ben Young

https://youngsolutions.net/wp-content/uploads/2019/08/logo-1.png

Ben Young2024-12-05 16:46:252024-12-05 16:52:53Machine Vision vs. Computer Vision: Understanding the Differences

https://www.youngsolutions.net/wp-content/uploads/2024/12/IMG_1389.1.jpg

1630

2174

Ben Young

https://youngsolutions.net/wp-content/uploads/2019/08/logo-1.png

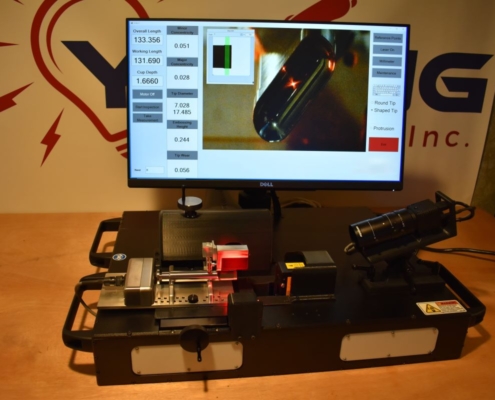

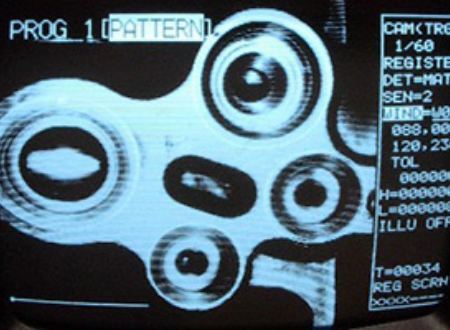

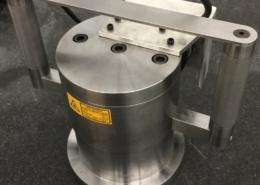

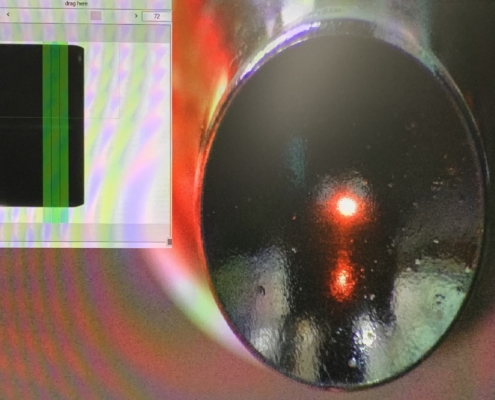

Ben Young2024-12-05 16:46:252024-12-05 16:52:53Machine Vision vs. Computer Vision: Understanding the DifferencesYoung Solutions specializes in the design of machines to solve unique customer requirements. Is your process a good candidate for the application of a vision inspection system?

We can assist with a feasibility analysis to determine if a vision system is a good fit for your process.Send us a few photos of the conditions from which you wish to differentiate, and we can provide quick examples of programs which will discern acceptable and unacceptable conditions.

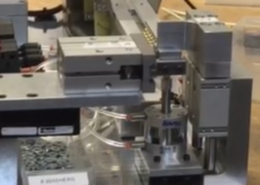

Vision is one of the most flexible of inspection methods for small to mid-size manufacturers. One of the considerations we often put in front of our customers is the potential re-use of this hardware in their operation. As the options with optical inspection systems continue to increase it has become more affordable to buy a system with options which are not immediately necessary to provide many opportunities for future utilization. We have helped small manufacturers re-purpose the same systems on numerous occasions. Your system could start on a screw machine, move to a cnc mill, and later to a final inspection area. It could just as easily start on a high speed conveying line, move to an automated inspection area, and finally a quality lab. You may have to change lighting or a lens but those additions add to later flexibility and the likelihood your inspection camera will be used for a very long time. However, if the budget dictates we can always optimize the components to assist you in hitting the price points you desire while satisfying the need at hand.

CASE STUDIES

COMPLETED PROJECTS

If you’d like to send us information about your project.

If you’d like to send us information about your project.

HELPFUL VIDEOS

Cognex Insight Tech Tips

Keyence Sensor Tracking

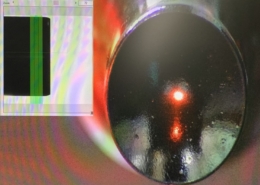

Depth of Field, Working Distance, & Aperture

Requirements for Reading Barcodes

Field of View/Resolution

Vision System Sorting Mechanism