Corrective Actions & Root Cause

DESIGNED BY: Young Solutions Inc.

Corrective Actions

Corrective Actions can be performed in many formats. Eight Discipline approaches are popular in the US and other formats like the A3 and Quality Problem Report are popular in specific industries. They all have a common underpinning with an approach to understand the root cause of a situation and follow up with corrective action.

Root Cause Analysis

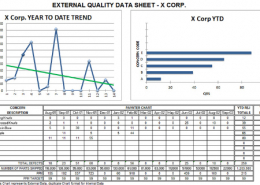

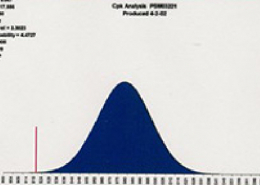

This part has a keyway which is cut on a CNC machine. The keyway was sometimes out of tolerance but process capability studies had shown this feature to typically be highly capable. The problem of oversize keyways seemed to occur infrequently and with a random pattern. Thinking there may be an issue with pressure the customer installed gauges for monitoring but no failures occurred during this evaluation.

Young Solutions assisted with the installation of a pressure transducer which was tied into the control logic of the system. This unit was able to pick up the infrequent drops in pressure that allowed the clamping system to relax enough to allow the part to move. These events were then associated with large power draws on the plants electrical distribution system that occurred when large machinery was turned on. While it was not possible to address this root cause, the transducers signal during these occurrences triggered additional controls to insure containment.

If you want to know more about the 8D process there is an article in the YSI blog.