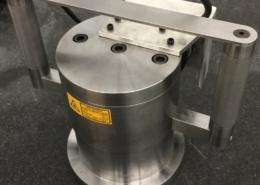

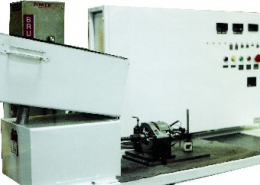

Rotary Die

DESIGNED BY: Young Solutions Inc.

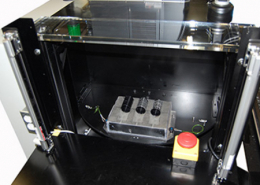

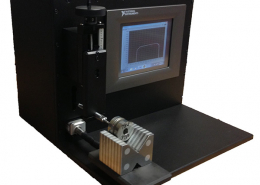

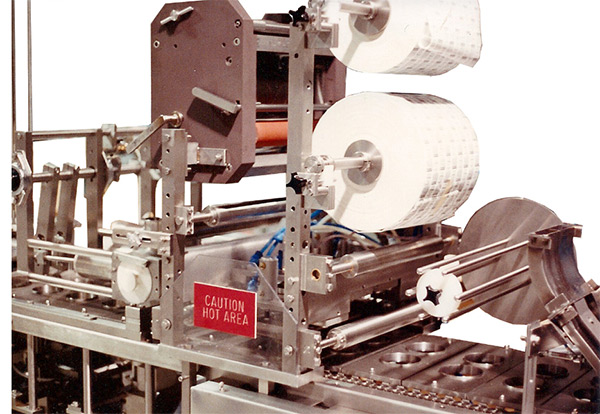

This particular project required the application of tamper evident seals to an ice cream container on the fly. The solution required the correct timing of high speed components coupled with managed pressures and thermodynamics to achieve a successful result.

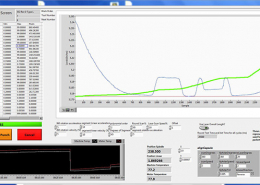

Young Solution’s machine takes hundreds of measurements and draws a profile of the surface along the axis of the bore providing a picture which can show the wear patterns develop over time. Because the wear areas in these profiles are apparent, they can be measured much more confidently.

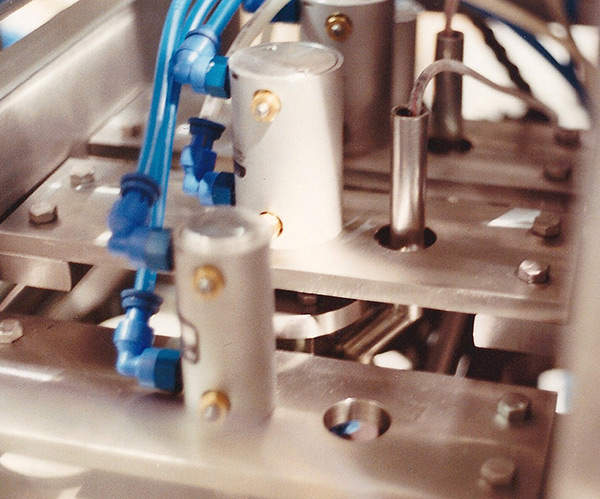

Heat sealer

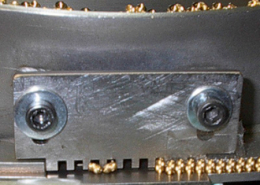

This sub assembly addressed several challenges involving on the fly die cutting and membrane sealing on an ice cream container:

- Synchronized action to heat seal a membrane to the top of a container, then strip away the waste material and move it out of the way

- Thermodynamic considerations with heat sealing on the rim of a container which is sometimes contaminated with ice cream. The solution required special materials, coatings, heaters, and an understanding of the relationships between, heat, cycle time, component timing, pressure, materials, web control, and the occurring dynamic movements.