Precision and Innovation: The Role of Laser Measurement

Young Solutions Inc.

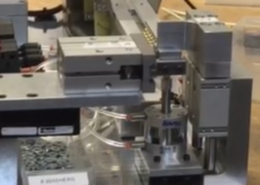

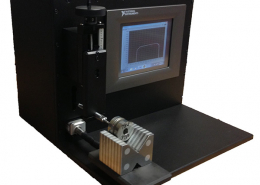

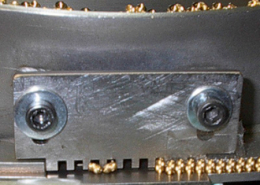

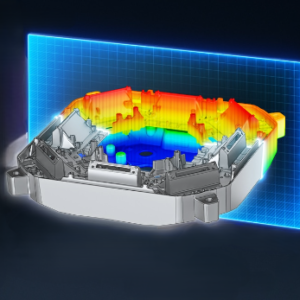

Scanning Laser in Special Fixturing for an Automotive Application

Precision and Innovation: The Role of Laser Measurement

Laser measurement technology has revolutionized the field of metrology, offering unparalleled precision, speed, and versatility. From manufacturing and construction to research and development, laser measurement systems provide accurate data essential for quality control, process optimization, and innovation. Let’s delve into the world of laser measurement and explore its applications, advantages, and future prospects.

The Science Behind Laser Measurement

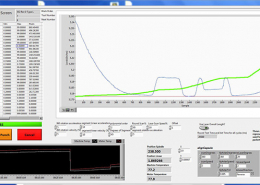

Laser measurement relies on the principles of laser light emission and reflection. A laser beam, which is a concentrated, coherent light source, is emitted towards the target object. The time it takes for the light to bounce back to the sensor is measured, and this time-of-flight data is used to calculate the distance, dimensions, or surface characteristics of the object with high precision. In other cases the beam is triangulated to calculate the distance.

There are several types of laser measurement systems, including:

• Laser Distance Meters: Measure the distance between the device and a target surface.

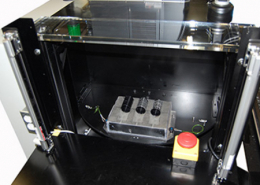

• Laser Scanners: Capture detailed three-dimensional data by sweeping a laser beam over a surface.

• Laser Interferometers: Measure extremely small distances and changes in distance with sub-nanometer precision.

• Laser Profilers: Generate precise cross-sectional profiles of an object’s surface.

Applications of Laser Measurement

Laser measurement technology is used in a wide range of applications across various industries:

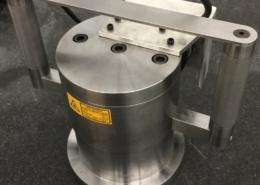

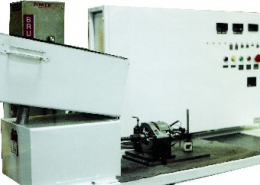

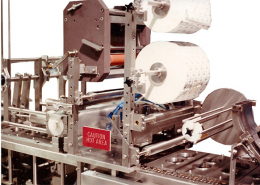

• Manufacturing: Ensures precise measurements for quality control, machining, and assembly processes.

• Construction: Facilitates accurate measurements for site surveys, building alignments, and material cutting.

• Automotive and Aerospace: Provides critical data for component fabrication, alignment, and testing.

• Medical Devices: Ensures the precision manufacturing of implants, instruments, and diagnostic equipment.

• Research and Development: Supports scientific experiments requiring high-precision measurements in fields like physics, engineering, and material science.

Advantages of Laser Measurement

The advantages of laser measurement over traditional methods are numerous:

• High Precision: Laser measurement systems can achieve extremely high accuracy, often in the sub-millimeter range.

• Speed: Laser systems provide rapid measurements, enabling real-time data acquisition and analysis.

• Non-Contact Measurement: Laser measurement is non-invasive and can be used on delicate or hazardous surfaces without physical contact.

• Versatility: Laser systems can measure distances, dimensions, surface profiles, and more, making them highly adaptable to various tasks.

• Ease of Use: Modern laser measurement devices are user-friendly, with intuitive interfaces and software integration for seamless operation.

Future Prospects of Laser Measurement

As technology continues to advance, laser measurement is expected to become even more precise, efficient, and versatile. Innovations in laser sources, optics, and data processing algorithms will enhance the capabilities of laser measurement systems. Additionally, the integration of laser measurement with other technologies, such as artificial intelligence and the Internet of Things (IoT), will open new possibilities for automation, remote monitoring, and smart manufacturing.

Laser measurement technology is a cornerstone of modern metrology, driving innovation and precision across numerous industries. Its ability to deliver accurate, rapid, and non-contact measurements makes it an indispensable tool for ensuring quality and efficiency in today’s fast-paced, technology-driven world. As advancements continue, the future of laser measurement looks brighter than ever.

Is there a specific aspect of laser measurement you’re particularly interested in? Contact us today.